We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for OEM/ODM China Made In Mini Engraving Fiber Marking Cnc Laser Cutting Machine, Are you still looking for a quality product that is in accordance with your good company image while expanding your product range? Try our quality products. Your choice will prove to be intelligent!

We've our have sales staff, style and design staff, technical crew, QC team and package workforce. We've strict excellent control procedures for each system. Also, all of our workers are experienced in printing field for Cnc Laser Cutting Machine, Fiber Marking Made In Cnc Laser Machine, Mini Engraving Cnc Fiber Laser Cutting Machine, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

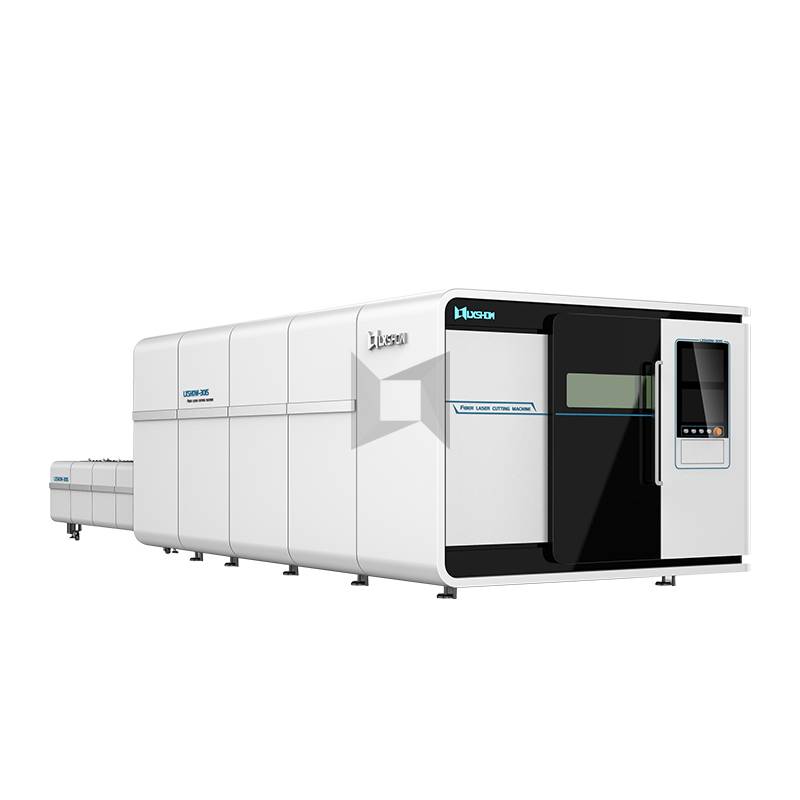

Applied materials : Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Applied Industry: Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

1. Excellent Path Quality: Smaller laser dot and high work efficiency, high quality.

2. High Cutting Speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable Running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High Efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low Maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7. Easy Operations: fiber line transmission, no adjustment of optical path.

| 1 | Machine Name | Small Metal Plate Fiber laser cutting machine |

| 2 | Model | LXF0640 |

| 3 | Laser machine cutting area | 600x400mm |

| 4 | Fiber Laser Power | 500w/750w/1000W |

| 5 | Laser wave length | 1064nm |

| 6 | Transmission system | High quality ball screw transmission |

| 7 | X.Y axis location accuracy | ±0.01mm |

| 8 | X.Y axis repeat location accuracy | ±0.01mm |

| 9 | X.Y axis max moving speed | 30m/min |

| 10 | Max cutting speed | 1--30m/min(it will according to metal material and laser power) |

| 11 | Cutting thickness | Detailed in the following cutting thickness |

| 12 | Application Material | Metal sheetIron/CS/SS/Aluminum/Copper and all kinds metal |

| 13 | Advantages | >Excellent beam quality >Simple , compact, electrically and optically efficient >Compatibly powerful and reliable >Maintenance free >multilingual, more than 11 foreign languages >3 years warranty . |

| 14 | Gross weight | 1200KG |

| 15 | Net weight | 1000KG |

| 16 | Machine size | 1910*1460*2060mm |

|

Materials |

Thickness(mm) |

Gas Type |

500W |

800W |

1000W |

|

Speed(m/min) |

Speed(m/min) |

Speed(m/min) |

|||

|

Stainless steel |

1 |

N2 |

10~12 |

16~20 |

20~24 |

|

2 |

N2 |

2 |

4.5 |

5.4 |

|

|

3 |

N2 |

0.7 |

1.7 |

2.2 |

|

|

4 |

N2 |

1.2 |

|

Materials |

Thickness (mm) |

Gas Type |

500W |

800W |

1000W |

|

Speed(m/min) |

Speed(m/min) |

Speed(m/min) |

|||

|

Carbon Steel |

1 |

Air |

8~9 |

7~10 |

9~12 |

|

2 |

Air |

4~5 |

5~6 |

6~8 |

|

|

3 |

O2 |

2 |

2.3 |

3 |

|

|

4 |

O2 |

1.5 |

1.8 |

2 |

|

|

5 |

O2 |

1.2 |

1.5 |

1.6 |

|

|

6 |

O2 |

0.9 |

1.3 |

1.4 |

|

|

8 |

O2 |

1 |

1.1 |

||

|

10 |

O2 |

0.6 |

0.9 |

||

|

12 |

O2 |

0.7 |

|

|

|

| Exchange table fiber optic tube cutter fiber tube cutter fiber laser tube cutting | Exchange table Full Cover fiber laser cutting machine | Hybrid laser mixed laser cutting machine Fiber |

|

|

|

| High Precision metal carbon steel | Big Power thick metal plate cnc fiber | Hot sale metal sheet |

VIEW MORE>>>>>

CONTACT US>>>>>

Click Here Contact Us For Free Sample

Applied materials : Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

Applied Industry: Applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment, elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

1. Excellent Path Quality: Smaller laser dot and high work efficiency, high quality.

2. High Cutting Speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable Running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High Efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low Maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7. Easy Operations: fiber line transmission, no adjustment of optical path.

| 1 | Machine Name | Small Metal Plate Fiber laser cutting machine |

| 2 | Model | LXF0640 |

| 3 | Laser machine cutting area | 600x400mm |

| 4 | Fiber Laser Power | 500w/750w/1000W |

| 5 | Laser wave length | 1064nm |

| 6 | Transmission system | High quality ball screw transmission |

| 7 | X.Y axis location accuracy | ±0.01mm |

| 8 | X.Y axis repeat location accuracy | ±0.01mm |

| 9 | X.Y axis max moving speed | 30m/min |

| 10 | Max cutting speed | 1–30m/min(it will according to metal material and laser power) |

| 11 | Cutting thickness | Detailed in the following cutting thickness |

| 12 | Application Material | Metal sheetIron/CS/SS/Aluminum/Copper and all kinds metal |

| 13 | Advantages | >Excellent beam quality >Simple , compact, electrically and optically efficient >Compatibly powerful and reliable >Maintenance free >multilingual, more than 11 foreign languages >3 years warranty . |

| 14 | Gross weight | 1200KG |

| 15 | Net weight | 1000KG |

| 16 | Machine size | 1910*1460*2060mm |

|

Materials |

Thickness(mm) |

Gas Type |

500W |

800W |

1000W |

|

Speed(m/min) |

Speed(m/min) |

Speed(m/min) |

|||

|

Stainless steel |

1 |

N2 |

10~12 |

16~20 |

20~24 |

|

2 |

N2 |

2 |

4.5 |

5.4 |

|

|

3 |

N2 |

0.7 |

1.7 |

2.2 |

|

|

4 |

N2 |

1.2 |

|

Materials |

Thickness (mm) |

Gas Type |

500W |

800W |

1000W |

|

Speed(m/min) |

Speed(m/min) |

Speed(m/min) |

|||

|

Carbon Steel |

1 |

Air |

8~9 |

7~10 |

9~12 |

|

2 |

Air |

4~5 |

5~6 |

6~8 |

|

|

3 |

O2 |

2 |

2.3 |

3 |

|

|

4 |

O2 |

1.5 |

1.8 |

2 |

|

|

5 |

O2 |

1.2 |

1.5 |

1.6 |

|

|

6 |

O2 |

0.9 |

1.3 |

1.4 |

|

|

8 |

O2 |

1 |

1.1 |

||

|

10 |

O2 |

0.6 |

0.9 |

||

|

12 |

O2 |

0.7 |

|

|

|

| Exchange table fiber optic tube cutter fiber tube cutter fiber laser tube cutting | Exchange table Full Cover fiber laser cutting machine | Hybrid laser mixed laser cutting machine Fiber |

|

|

|

| High Precision metal carbon steel | Big Power thick metal plate cnc fiber | Hot sale metal sheet |

VIEW MORE>>>>>

CONTACT US>>>>>