Digital knife cutting machine suit for leather, fabric, textile, cardboard, plastic box, fiber glass,corrugated cardboard, sticker, film, foam board,rubber, cloth, gasket material, garment cloth, footwear material, bags materials, non-woven fabrics,seat cover, carpets/rugs, sponge, PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE and composites.

1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance;

2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life;

3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc.

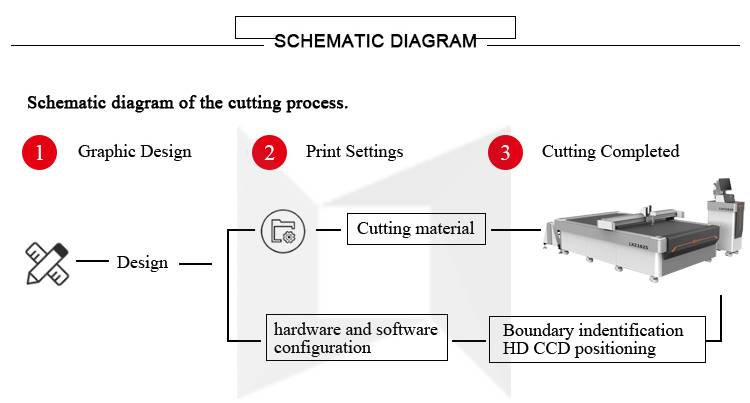

4. Digital cutting machine was designed easy to install, set-up and operate;

5. Being equipped with infrared sensor and emergency stop devices, guarantees safety;

6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

7.Automatic feed cutting machine, it is suitable for coil automatic cutting, automatic feeding, automatic blanking, continuous cropping is suitable for batch processing products.

8.CCD visual identification cutting machine can identify the leather, leather and other precious irregular outline of the materials, automatic identification material flaws, automatic super typesetting, contrast artificial typesetting save material by more than 10%.

|

Model |

LXZA1660 |

|

Working area |

1600×6000mm |

|

Machine size (mm) |

2150*7000*1350 |

|

Rated power |

11KW |

|

Fixed mode |

Auto feeding type table |

| Multifunctional head |

Swiss imported knife: with vibration full cutting, vibration half cutting and cursor location function. |

|

Tool configuration |

Multiple cutting knives |

|

Safety device |

Using infrared sensors, responsive, safe and reliable. |

| Translational

velocity |

800-1200mm/s |

|

Cutting speed |

200-800mm/s(according to different cutting materials) |

|

Cutting thickness |

≤22mm(according to different cutting materials) |

|

Cutting materials |

Leather, all kinds of clothing flexible material, Sponge composite leather, PVC, soft glass, Silicon, rubber |

|

Repeated accuracy |

≤0.1mm |

|

Capacity |

2GB |

|

Transmission system |

imported(Digital servo motor, linear guide, synchronous belt, ball screw) |

|

Instruction system |

HP-GL compatible format |

|

Voltage |

380V±10% |

|

Other configuration |

Japanese Yaskawa servo motor,Germany imported conveyor belt, vacuum table, auto feeding, Taiwan Hiwin rail, 9.0kw vacuum pump (We can customized machine production as your requirements) |

|

Machine Weight:KG |

2500 |

|

|

|

|

1625 CNC Vibrating Knife Cutting Machine |

CCD Cnc Vibrating Knife Cutter 1625 |

Auto Feeding Vibrating Knife Cutting Machine 1625 |

CCD Auto Feed Cnc Vibrating Knife Cutting Machinery |

|

|

|

|

CCD Automatic Cnc Oscillating Knife Cutting Machine 1625 |

round knife fabric leather cloth cutting machine 1660 |

Auto Feeding Cnc Vibrating Knife Cutting Machine 1625 |

1625 Cnc Vibrating Knife Machine |

VIEW MORE>>>>>

CONTACT US>>>>>

Click Here Contact Us For Free Sample

Digital knife cutting machine suit for leather, fabric, textile, cardboard, plastic box, fiber glass,corrugated cardboard, sticker, film, foam board,rubber, cloth, gasket material, garment cloth, footwear material, bags materials, non-woven fabrics,seat cover, carpets/rugs, sponge, PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE and composites.

1. Imported Taiwan square linear guide and Japanese servo motor ensure high accuracy, fast cutting speed and stable working performance;

2. Whole machine is welded with thick square seamless steel structure and treated with high temperature, ensures high accuracy, no deformation and super long service life;

3. The whole piece aluminum platform is honeycomb structure, not easy to deform, sound-absorbing, etc.

4. Digital cutting machine was designed easy to install, set-up and operate;

5. Being equipped with infrared sensor and emergency stop devices, guarantees safety;

6. Cutting by knife not laser, no air pollution, no burnt edge, cutting speed is 5-8 times faster than laser cutting machine;

7.Automatic feed cutting machine, it is suitable for coil automatic cutting, automatic feeding, automatic blanking, continuous cropping is suitable for batch processing products.

8.CCD visual identification cutting machine can identify the leather, leather and other precious irregular outline of the materials, automatic identification material flaws, automatic super typesetting, contrast artificial typesetting save material by more than 10%.

|

Model |

LXZA1660 |

|

Working area |

1600×6000mm |

|

Machine size (mm) |

2150*7000*1350 |

|

Rated power |

11KW |

|

Fixed mode |

Auto feeding type table |

| Multifunctional head |

Swiss imported knife: with vibration full cutting, vibration half cutting and cursor location function. |

|

Tool configuration |

Multiple cutting knives |

|

Safety device |

Using infrared sensors, responsive, safe and reliable. |

| Translational

velocity |

800-1200mm/s |

|

Cutting speed |

200-800mm/s(according to different cutting materials) |

|

Cutting thickness |

≤22mm(according to different cutting materials) |

|

Cutting materials |

Leather, all kinds of clothing flexible material, Sponge composite leather, PVC, soft glass, Silicon, rubber |

|

Repeated accuracy |

≤0.1mm |

|

Capacity |

2GB |

|

Transmission system |

imported(Digital servo motor, linear guide, synchronous belt, ball screw) |

|

Instruction system |

HP-GL compatible format |

|

Voltage |

380V±10% |

|

Other configuration |

Japanese Yaskawa servo motor,Germany imported conveyor belt, vacuum table, auto feeding, Taiwan Hiwin rail, 9.0kw vacuum pump (We can customized machine production as your requirements) |

|

Machine Weight:KG |

2500 |

|

|

|

|

1625 CNC Vibrating Knife Cutting Machine |

CCD Cnc Vibrating Knife Cutter 1625 |

Auto Feeding Vibrating Knife Cutting Machine 1625 |

CCD Auto Feed Cnc Vibrating Knife Cutting Machinery |

|

|

|

|

CCD Automatic Cnc Oscillating Knife Cutting Machine 1625 |

round knife fabric leather cloth cutting machine 1660 |

Auto Feeding Cnc Vibrating Knife Cutting Machine 1625 |

1625 Cnc Vibrating Knife Machine |

VIEW MORE>>>>>

CONTACT US>>>>>